While a single 250 or 300 hp is the perfect power to achieve great performances , if the owner request a non compromise safety and deep water cruising, twin engines option is the right choice and 2x115/2x140 hp outboards, allow to achieve more than 40 knots keeping fuel economy in a 1.3/1.4 liters per nautic mile at cruising speed. And for high demanding users , the boat can handle up to 2x225 hp (Champion Edition version) for 60 and more knots, equipped with shock mitigating seats and a dedicated twin stepped hull. Hull thickness has been increased as 6 mm standard, like Akes 23 XS version.

The material is marine grade alloy 5083: it is durable, tough, light, number one for impact resistance, can be painted or not.

COMFORT

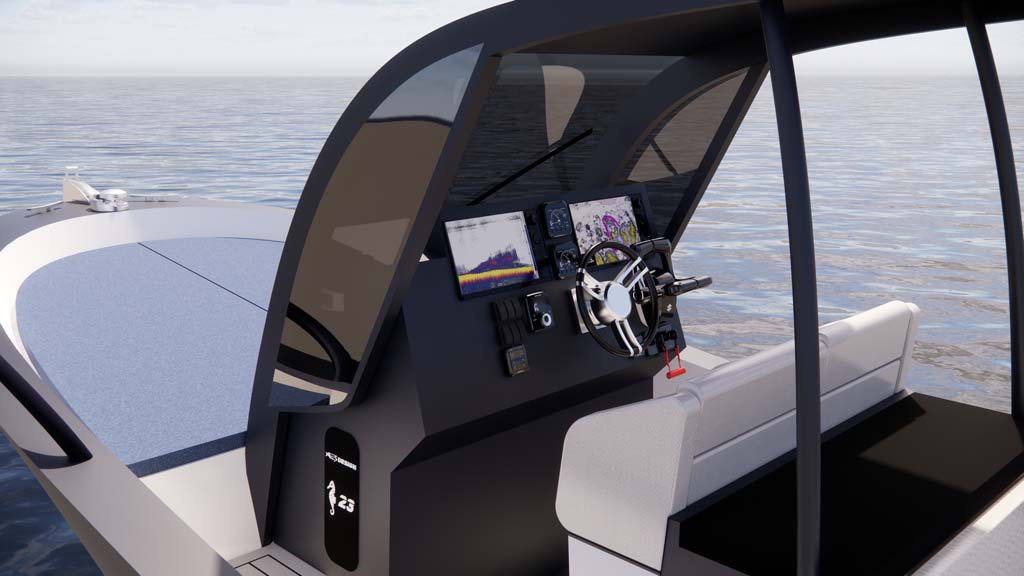

The double side is filled with foam, like a rigid inflatable, and the hull is divided by watertight bulkheads and the compartments are foamfilled: it means the Akes 23 is unsinkable. The winglets are designed to keep a low planing speed, and an amazing grip in hard turns. In this hull, tested for several years during any condition in angry Sardinian West Coast , and that has been reliable and affordable, has been designed a new deck layout that makes the Akes 23 even larger and comfortable. All the areas of the boat have been deeply studied in order to give the maximum of versatiliy, space and comfort for all the activities. At the stern, a large extended swim platform with low transom gives a comfortable access to the bath area. The cockpit is wide and without barriers or obstacles: two longitudinal benches are perfect for moving free in the aft deck, can be fitted with live bait tank,are useful as big lockers , as seats when you have a lunch in the boat. These joined to the sternwards bolster seat could hold 8 persons seating or 10 with other 2 removable seats. It is a record for a 23 feet boat. The bolster seat has the space to fit a fridge, a sink, a kitchen, and the cover can be 180° folded to become a lounge table . Under the bolster there is enough space to stow a little inflatable tender.All the helm area can be closed to make the Akes 23 WA a cabin pilot boat, it is helpful for the cold days, or simply as a wind protection. The consolle is 1.10 m in width, it is a all-plan surface, so there is more than enough space to place any type of instruments, tv, gps, tablet,hi-fi, vhf, echo, etc; and the windshield glass with wiper helps you in strong during rough wind navigation. Inside the consolle there is the WC, in which you can enter through a front access door: simple, smart, hidden, and the more important, separated from the other areas, included cabin. The aluminum Air-top has no fabric: low maintenance, light, and aerodynamic: the four pipe supports are good to hold when you navigate in rough conditions at high speed. The access towards the fore area is given by two large steps, empty inside, useful to stow as usual some small things. The bow sundress is KING SIZE, with its 2,30 m in lenght and 2 m in width, but it is not all: the front part of the consolle has a big cushion to have another relax area, useful during navigation or afloat. Is there a better way for reading? The big locker under the sundress is 2m long and 1.60 wide. It can carry all the things you imagine, but it can also be transformed in cabin to spend the night onboard. In this case the separate WC is even more appreciated.

SIMPLICITY AND FUNCTIONALITY

All the boat is inspectable, rational, and the maintenance is easy. Batteries and bilge are under the stern locker; the helm seat is fixed over the gasoline locker, so if you have to remove the tank, the procedure is simple. Just remove the bolts. Electric plants and instruments are visible from the consolle's front door. The windlass is accessible from the bow.

FOR FISHING

The wide and flush-deck open cockpit gives you the maximum freedom during fishing activity. The like bait and the fishing rods are enough and well-positioned. The construction material is rugged and the antiskid deck keeps away the worries for dirtying: just like in the old fishing boats. Of course the entire floor can be fitted with teak, or for heavy-duty works, with Treadmaster. The inner gunwhale pad can be placed to help the fisherman when catching a big prey;a modify in the sides with space for legs is possible as the boat can be customized for the demanding fisherman.

ECONOMY

The simplicity of various solutions, and the aluminum hull- without molds, keeps the costs at reasonable levels, but the overall use economy is the strong point. Akes 23 WA can be powered with one engine to achieve great performances, and this is an advantage for the purchase price; the low fuel consumption and the hydrodinamics of the hull make the rest: the gasoline needed will be the same of most smaller ribs or boats and way lower than classic and "famous" heavy walkarounds of fisherman boats that need the twice of achieve the same performances. The marine grade alloy isn’t afraid to stay in the water, no risk of osmosis or decrease of the mechanic property of the material (fiberglass for example suffer a lot to stay in the water and suffers also the sun and the temperature variations). It is only needed to change the zync anodes once a year. The low weight (1200 kg for the hull), and the beam of 2.48 m , means that the Akes 23 is trailerable.The range is about 250 Nautic Miles with the gasoline 300 L tank.

INNOVATION

For the Akes 23 project has been used latest technologies . CAD-CAM softwares to check the plate developements, nesting files (all the patterns are cutted by Laser); it has been used the FEA simulation to check stiffness, softwares to verify stability and buoyancy, and also the CFD for performance analysis. At the end, it has been built a scale model using 3D printers.

MAIN Specifications:

- Lenght: 7.50 m

- Beam: 2.48 m

- Depth: 1.71 m

- Draught: 0.4 m

- Persons load: 7

- Dry weight.. : 1200 Kg

- Displacement: 2000 kg

- Power: 1x250 to 2x225 outboards

- Speed: from 38 up to > 60 knots

- Fuel consumption with 2x140 hp : 25 liters per hour at 20 knots